Find Parts For Your Vehicle

Featured Categories View All »

Top Products

Price: $208.99

Price: $31.99

Price: $233.99

Price: $209.99

Price: $440.99

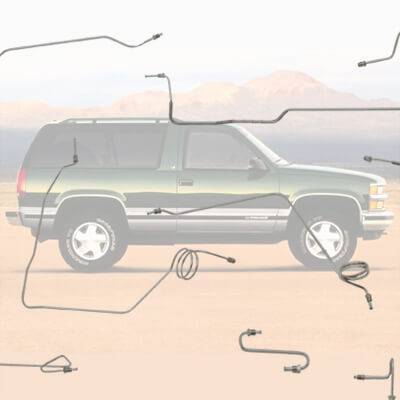

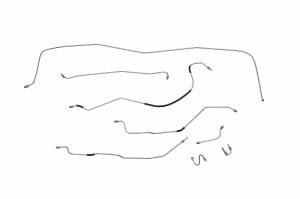

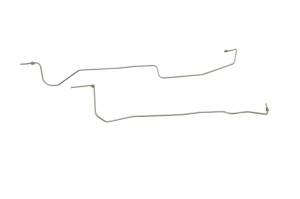

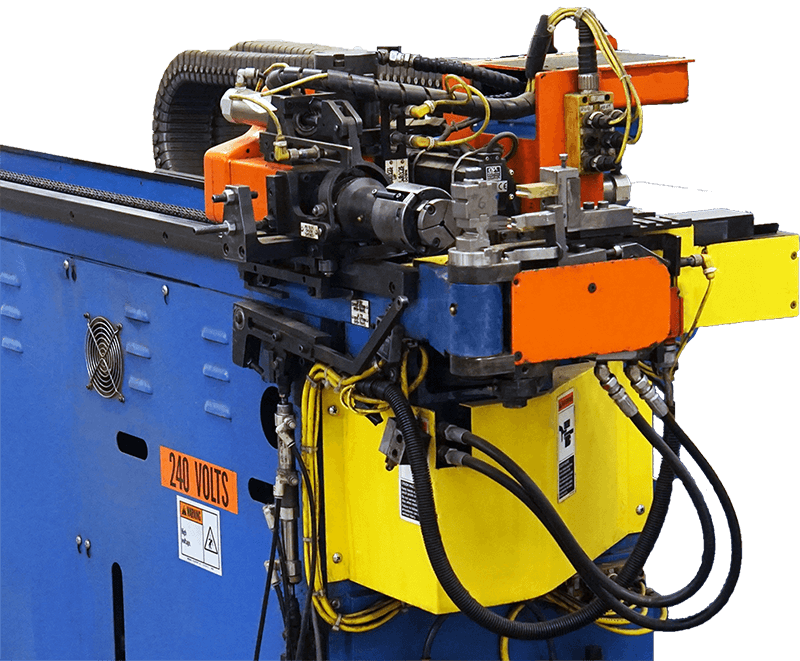

Classic Tube is the leader in the preformed tube bending industry. We can iterate virtually identical parts on an infinite scale by leveraging industry leading CNC tube bending technology non-contact laser scanning, and our highly experienced engineering team. These allow us to produce long lasting tubing with extreme accuracy, competitive pricing, on schedule delivery, and knowledgeable customer service.